Engine Tech I: Torque and Horsepower - What's the Difference?

Many people who are self-described "gearheads" often have very little understanding of just how an internal cumbustion engine actually makes power, and two properties that are commonly misunderstood are torque and horsepower, specifically the difference between the two and their relationship to each other. Here we will try to clear-up some of this confusion without getting too involved in the theory and mathematics involved, although we cannot totally ignore either. When possible, any discussion or reference to the math and physics associated with engine dynamics will be limited to what is relevant to the discussion and kept in simple terms so those without degrees in engineering can understand them and apply them practically.

Many people who are self-described "gearheads" often have very little understanding of just how an internal cumbustion engine actually makes power, and two properties that are commonly misunderstood are torque and horsepower, specifically the difference between the two and their relationship to each other. Here we will try to clear-up some of this confusion without getting too involved in the theory and mathematics involved, although we cannot totally ignore either. When possible, any discussion or reference to the math and physics associated with engine dynamics will be limited to what is relevant to the discussion and kept in simple terms so those without degrees in engineering can understand them and apply them practically.It is already assumed that the reader has a basic familiarity and knowledge of the mechanical parts of an engine, so many terms used in that regard will not be defined along the way. You can refer to this automotive dictionary of terms for further clarification.

Torque

Basically, torque is the measurement of force applied to rotate an object around a pivot point at specific distance (radius) from the pivot point. In very simple terms, think of a wrench and a bolt. The closer you put your hand to the pivot point on the wrench, the more effort or force you will need to tighten or loosen the bolt; the further away, the converse is true. In common parlance, many will call this leverage. Go here and here for more in-depth discussion if you feel so inclined to indulge in more of the physics and math.

Now, let's consider this in terms of an engine. Our pivot point would be the crankshaft centerline, and our radius arm is the connecting rod journal. The measurement of the distance between the rod journal centerline and the crank centerline determines the stroke. Thus, the longer the stroke, the more torque will be applied to the crankshaft. The movement of the piston in the cylinder applies a certain amount of force to rotate the crankshaft, keeping in mind that there is also a certain amount of force required to rotate the crankshaft, which is determined by many factors including (but not limited to) internal resistance (namely rotational component mass and friction) and external resistance (commonly referred to as "load") such as vehicle weight, aerodynamic drag, gearing, inclines, etc.

Horsepower

Here's where things get tricky. The first thing to remember is that there is no such thing as horsepower - per se. While torque can be measured, horsepower is a calculation of torque measured against a time factor.

Let's use a simple example. Two people, standing atop a structure 20 feet above ground, are each holding a rod with a 20 foot length of rope attached to it and attached at the other end of the rope is a 10 pound weight. Both are able to twist the rod and raise the weight from the ground, thus they are able to apply the same amount of torque. Now they are going to have a race against the clock to see who can lift the weight to the top in the shortest amount of time. The one who can do it the fastest will be the one who applies the most power. In other words, while both are able to apply the same amount of torque, the one who can raise the weight to the top the fastest is able to apply that same amount of torque faster - that is, twist the rod faster to perform more work.

In terms of an engine, that time factor is engine (specifically, crankshaft) RPM. Horsepower is calculated using the following formula:

HP = (torque x RPM)/5252

James Watt first determined the concept of horsepower and its calculation using dray horses to pull a certain amount of weight for a given distance in a certain time period.

The unit, horsepower, was originated by James Watt (1736-1819), the Scottish engineer who developed the first practical steam engine. When Watt offered to sell his steam engines to farmers and miners, he was probably asked how many horses they would replace. The value of the horsepower was based on his experiments with strong dray horses that were able to do about 50 percent more work than a standard horse in a working day. He concluded that an average draft horse could steadily exert a 150 pound force while walking at a speed of 2.5 miles and hour. The horse thus performed work at the rate of 33,000 foot-pounds per minute, or 550 foot-pounds per second. Watt defined this rate as 1 horsepower.Read that entire piece if you want to know how the constant of 5252 was derived as well as the origin of the term "brake horsepower" and how a dynomometer works. It is worth noting that, while in America and other countries, the unit of power is horsepower (SAE) although there are variations like the German DIN, while in other countries such as New Zealand and Australia engine power is rated in kilowatts. Also worth noting is that, while in America torque is still measured in lbs./ft., elsewhere it is measured metrically in kiloPascals (kPa) or Newton-meters (Nm).

We now have defined torque and horsepower and have a glimpse of the relationship and differences between the two. It should be clear that based on our formula we can see that more power can be achieved by increasing torque at a given RPM or increasing RPM - or both. Let's take a look at some sample graphs I've prepared to further illustrate this relationship.

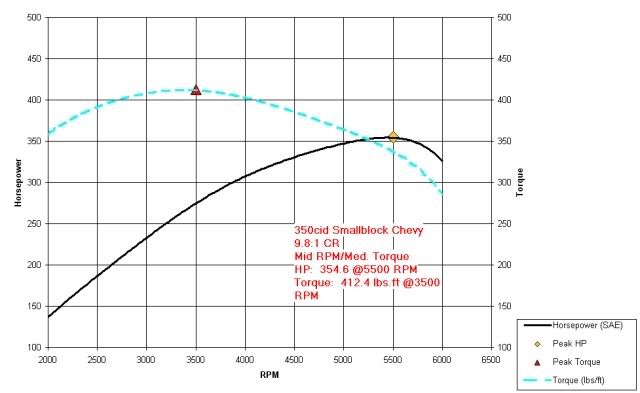

Using some common variations of a small-block Chevy, let's first examine a typical stock bore and stroke 350cid (4.00" x 3.48"), very similar in power specifications to the ZZ4 crate motor available from Chevrolet.

The first thing you should notice is the relatively flat torque curve with the "meat" of the power over 350 lbs./ft. "under the curve" from 2000 - 5000 RPM. This engine build is relatively easy to obtain using pump gas and "off the shelf" parts. There is nothing exotic involved here, and this engine would make a great "daily driver" for most any vehicle from a street rod to a pick-up, with lots of punch available throughout the RPM range making gear selection less critical.

The second thing you should take notice of is that, based on the formula and the rules of math, horsepower and torque will always be equal at 5252 RPM - if 5252 is a factor in the dividend and the divisor they will cancel each other.

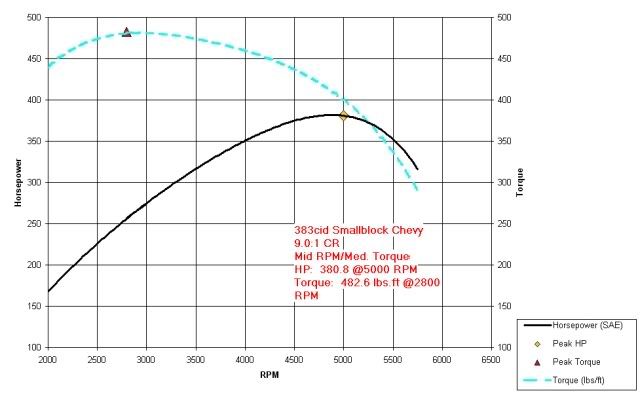

The next graph represents a stroked smallblock of 383cid which is obtained using a stock bore of 4.00" but a crankshaft stroke of 3.75" from the 400cid Chevy. This requires machining down the crankshaft main journals to fit the 350 block, but these cranks have been available for several years from mail-order parts houses ready to drop in. Chevy and many aftermarket sources also make this as a crate engine available with similar power.

You'll notice a nice, fat torque curve down low in the RPM range, offering over 400 lbs/ft. throughout the entire operating range and over 450 lbs./ft. under the curve from just over 2000-4000 RPM. This would make for not only another daily driver but also a great engine for a tow vehicle or any application where heavy weight/high load is involved. You should see a trend developing by now, namely that emphasizing low-end power results in a trade-off sacrificing some top-end power (even though this engine makes more power and torque, that is mostly due to increased displacement. The idea is to look at the shape and slope of the torque curve and where peak torque and HP occur).

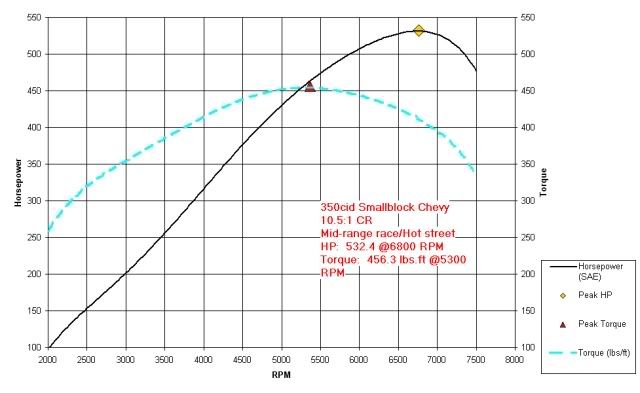

These next two examples take us in the opposite direction, trading-off low-end power for top-end power. Here is another 350cid Chevy that pushes the envelope of what would be usable in street applications. The engine would still be pump gas friendly provided that aluminum heads are used along with a good cooling system, but it is not what I would consider a daily driver. Careful parts matching in the intake, exhaust, and ignition systems is necessary to achieve these power numbers. Some careful engineering needs to be considered, as well, especially in the bottom end of the rotating assembly. In limited street and drag racing use where the upper RPM range is seen only in short bursts you could use a two-bolt main bearing block and cast pistons. For extended use such as road racing where the engine would see the upper RPM range exploited for longer periods a four-bolt assembly should be considered as a must, as well as good quality forged crank, rods, and pistons. It should be obvious that this motor isn't designed for a van, pick-up or '59 Caddy build, but it would do nicely in a 'Vette, Cobra kit car, T-bucket, or any other medium to light weight vehicle where off-idle/low RPM performance is not critical. Gearing is definitely a factor to be considered regardless of the application.

Notice that peak torque at 5500 RPM is quite high, yet for a racing application it still has a wide torque range, offering over 400 lbs./ft. from roughly 3700-7000 RPM and over 350 lbs./ft. starting at 3000 RPM through to redline.

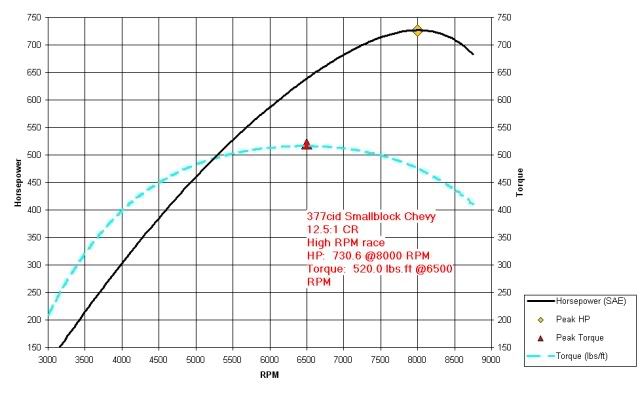

Our final example, a 377cid smallblock, is another variation based on de-stroking a 400 block bored .030" over to 4.155" and using the 3.48" stroke of a 350, representing the upper limits of what can be achieved with a normally aspirated smallblock. Although it wasn't too long ago that NASCAR cup engines (limited to 358cid using the 400 bore and a short stroke 3.25" crank) were making this kind of power, (now they are making nearly 100 more horsepower), and some drag racing smallblocks are making over 900 horsepower, these power figures are still at the extreme end. This is max-effort racing territory with high compression requiring minimum 100 octane gasoline. All engineering aspects are critical, and many exotic parts and precision machining are required to not only achieve these power levels but, also, to ensure that the engine lives past the break-in and tuning runs. This is not a "slap it together" affair to be accomplished on a shoe-string budget. Be prepared to spend some serious cash.

You'll see that peak torque is at 6500 RPM, and I must admit that achieving a torque curve as flat as this one would require a lot of work by somebody with very good knowledge of all the "little tricks" to make it happen. In other words, the horsepower can be made, but the torque curve would more than likely be a bit more "spiked" or "peaky" in the real world.

Summary

Hopefully, the reader will come away from this tutorial with a little better knowledge and understanding of the relationship between torque and horsepower. There is an old adage that sums it up pretty well: "Torque is acceleration, horsepower is miles per hour." Basically, what that means is that torque is what pushes you back in your seat and moves you down the road; horsepower is what determines how fast you will end-up going.

The other idea that you should grasp is that when building an engine, you are building for torque and where it occurs in the RPM range of the engine. Horsepower will take care of itself.

In future installments we will examine different aspects of how to build for torque in different applications, looking at physical properties like Brake Mean Effective Pressure (BMEP), Mean Intake Gas Tract Velocity (intake tuning theory), Sonic/Pressure Wave Theory (exhaust tuning), camshaft profiling and valve timing, and much more.

Labels: Engine Tech, Engineering, Racing, Science/Technology/Inventions

4 Comments:

Good stuff Joe

BobF

Hey Joe,

Great Info my friend! I think I remember you knocking the crap out of Randy when we were having a discussion about this exact same subject... Ahhh. The good ole days at Turnkey :)

Cheers!

Thank you for that explanation. Stroke it long and make it breath!

Blake - glad you liked the article. There will be more to come.

"Stroke it long..."

True if you're after low RPM torque, but long strokes tend to work against you if high RPM torque is what you're after; it has to do with inertia. Then you want a large bore to stroke ratio - that's why NASCAR engines use the large bore of the 400 but the short stroke of the 327.

It all depends on what you're going for.

Post a Comment

<< Home